BetterSoil Alliance aims to provide practical solutions for California’s drought-stricken almond industry

By Douglas J. Guth

With an ongoing drought threatening the future of California’s $6 billion almond industry, Yara International is spearheading a plan to improve soil health and water productivity, giving a boost to farmers whose livelihoods depend on the crop.

In pursuit of more sustainable farming practices, Yara launched the BetterSoil Alliance last October alongside agriculture tech company Heliae Ag. Through the effort, sustainability-focused solutions are being put into practice in 3,000 acres of California’s San Joaquin Valley, home of the nation’s largest almond growers. Overarching goals include a decreased carbon footprint of almond production as well as long-term viability for the industry.

According to estimations by the U.S. Drought Monitor, over 97% of the Golden State is experiencing “severe drought” conditions, with the most extreme impacts suffered by the food-producing regions of California’s Central Valley. Water scarcity, drought and rising temperatures have combined to prevent almond growers—not to mention farmers of all kinds—from properly maintaining their crops.

“There’s no doubt that this is a challenging situation for the almond industry,” says Devin Clarke, Almond Crop Manager at Yara. “We’ve seen an increase in orchard removal, and farmers who don’t have the resources to continue farming even with individual orchards at maximum production capacity.”

Restricted by a limited water supply, some California growers are seeing poor crop results, from nut shrivel, yield loss, to various physical imperfections that change the way they market their product. Increased costs in fertilizer and chemical inputs—together with logistical bottlenecks at shipping ports—has left farmers with excess supply and an attendant drop in crop prices.

These ongoing issues spurred Yara to take action with Heliae as a partner on the soil biology side, says Clarke.

The alliance reflects Yara’s holistic strategy in developing a “nature-positive food system,” encompassing the company’s expertise around enhancing crops and soil health while reducing larger impacts on the environment.

Yara’s Incubator Farm in Modesto is a test bed for this work, utilizing 80 total acres of almonds and walnuts. The almonds program focuses on comprehensive nutrition management and overall return on investment resulting in double-digit improvements around yield, water productivity and nitrogen use efficiency

Production, profitability and sustainability are principles of the alliance as well, notes Clarke. To meet those goals, about 100 California farmers have access to crop nutrition and soil management solutions produced by program partners—a low carbon footprint calcium nitrate fertilizer from Yara and Heliae’s PhycoTerra soil microbial food. Together, these products can drive almond yield and quality, while also improving soil health.

“In working with Heliae, we understood there’s an opportunity to enhance the structure and resiliency of soil,” Clarke says. “It’s a natural fit because of the aspirations of both companies around practical changes to improve soil health.”

A unique solution in the field

The new crop season kicked off in February, meaning it will be months until officials can determine the program’s full impact on this year’s nut harvest. However, independent third-party trials outside the alliance have shown a crop-per-drop improvement in water productivity when utilizing the calcium nitrate and PhycoTerra products in tandem.

Alliance leaders have also tasked new technology partners—PhyTech, Bountiful, and Ceres—with providing data points to build out a digital platform that supports aggregation, analysis, and visualization of program results. Upon comparing metrics like tree moisture stress in treated and untreated orchards, growers can more easily identify lasting solutions. Bringing in tech-focused partners further helps the alliance answer critical questions for farmers uncertain about supporting the cause, says Vice President of Yara North America Debbie Watts. Real-time access to combined data sets facilitates accelerated decision making opportunities for participating growers.

“We have this unique solution, but how do we know what’s happening in the field?” says Watts. “The platform is getting us tangible results on tree health, plus information on in-season production. Growers can include irrigation scheduling into the platform, and input what products they’re using and when.”

NDVI (Normalized Difference Vegetation Index) imagery from Ceres allows farmers to assess their crop canopies along with individual plant vigor. Participants meeting certain percentage increases in water productivity will receive up to $5,000 at the end of the two-year program.

“The focus right now is on high-value crops that go into food production, because we know these crops have significant decarbonization goals that companies need to hit,” says Watts.

Expanding the alliance’s footprint will be a focus in the months and years ahead. The program’s full reach is forecasted at 50,000 acres, a figure that would cover a wide range of soil types and site conditions, says Yara almond expert Clarke.

“There’s been a bit of reluctance at first from growers, because soil health and sustainability are ambiguous terms that vary in their definitions,” Clarke says. “With crop input prices going up, farmers are just trying to stick with what they know. But growers are convinced by the alliance’s overall intent around nitrogen use efficiency and water usage.”

Education around the alliance centers on its potential value beyond increased yield. Watts stresses a community aspect that brings together farmers, advisors and food companies on the most pressing challenges facing the marketplace.

“Bandwidth is an issue in talking to everyone we need to talk to,” says Watts. “Also, the concept around soil health is an educational process. We’re talking about the impact soil can have when you take measures to improve it.”

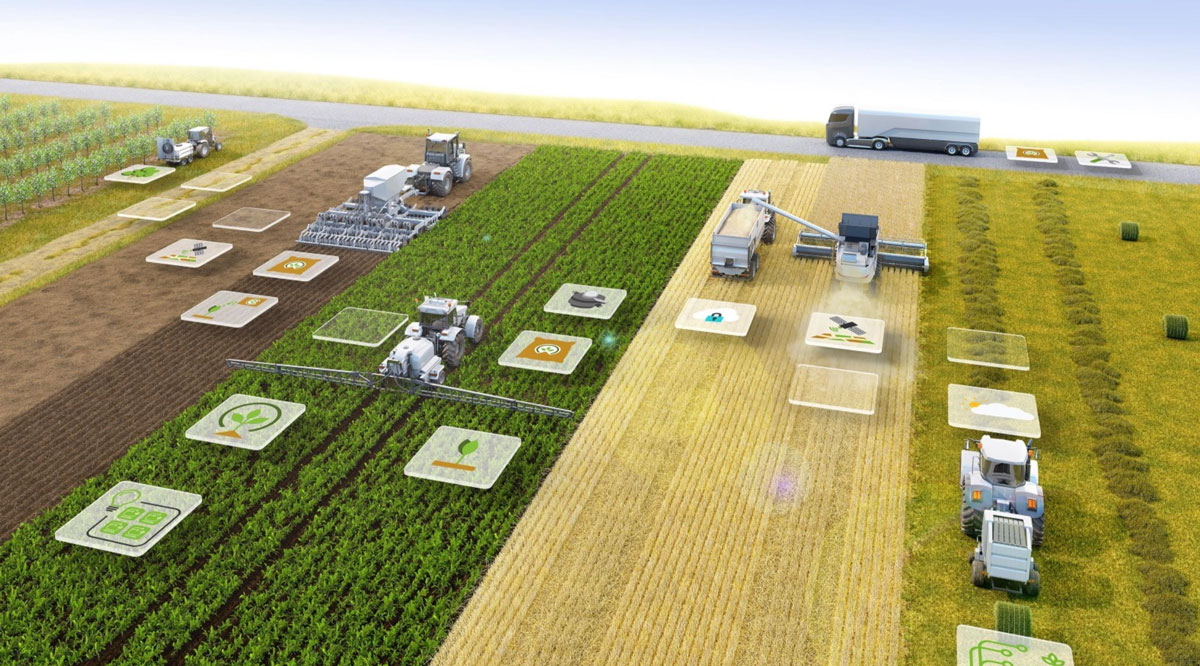

The cooperative is utilizing Raven’s driverless system for its own processes, along with a portion of its 6,300 member-growers in North and South Dakota. Using the innovation, Agtegra hopes to streamline operations through a high-tech platform that transforms existing equipment – whether a spreader, sprayer or spinner – into an autonomous machine.

The cooperative is utilizing Raven’s driverless system for its own processes, along with a portion of its 6,300 member-growers in North and South Dakota. Using the innovation, Agtegra hopes to streamline operations through a high-tech platform that transforms existing equipment – whether a spreader, sprayer or spinner – into an autonomous machine.

It’s been said many times: “If the product is free, YOU are the product.”

It’s been said many times: “If the product is free, YOU are the product.”  Erich Eller, a long-time industry veteran and the owner of independent crop consulting business ForeFront Ag Solutions, has experienced the shift to a just-in-time agronomic approach firsthand. It’s his job to help customers use the latest technologies to improve production and the bottom line.

Erich Eller, a long-time industry veteran and the owner of independent crop consulting business ForeFront Ag Solutions, has experienced the shift to a just-in-time agronomic approach firsthand. It’s his job to help customers use the latest technologies to improve production and the bottom line.