Yara’s Adapt-N software is a field-proven innovation for measuring nitrogen uptake in corn.

By Douglas J. Guth

PrecisionAg Alliance Contributor

Precision agriculture is sustainable agriculture, particularly when harnessing the high-tech tools currently transforming that ideal into reality, says Yara International Digital Sales and Business Development Advisor Bret Shaw.

To that end, Yara is boldly guiding precision into the hotly competitive agtech sector. Via the multinational chemical company’s Adapt-N software, farmers now have a field-proven innovation that actively monitors nitrogen uptake in corn. Through its precise measurement capabilities, the solution recommends nitrogen use efficiency rates to ensure maximum return on investment.

“Adapt-N is unique in the sense that it brings both profitability and sustainability into the marketplace through nitrogen-use efficiency,” says Shaw. “Yara is going through a digital transformation, which is bringing new and improved precision tools to the market.”

Developed at Cornell University, the technology was initially commercialized by agricultural field modeling company Agronomic Technology Corp (ATC). Yara acquired ATC in 2017 with an eye on new nitrogen management solutions for farmers, agricultural retailers and technology firms.

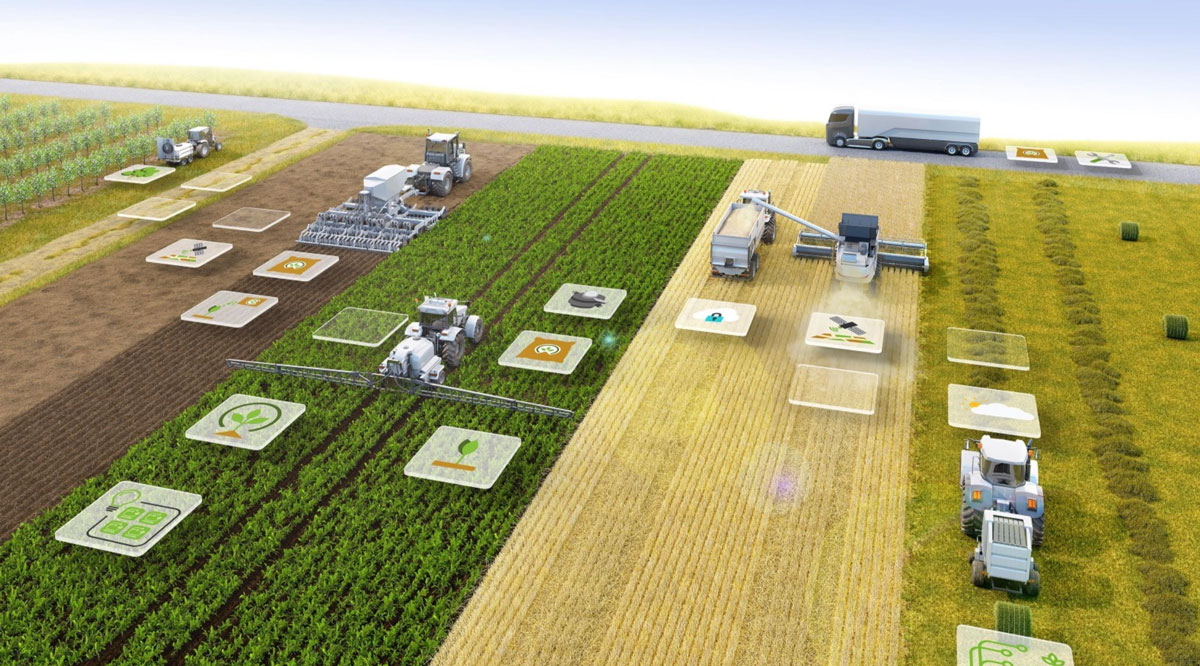

Adapt¬-N combines soil, weather and field specific data with meticulous crop modeling and field management. Yara, a Norwegian chemical producer dealing in fertilizers, animal nutrition and industrial biologicals, views the technology as a means for detailed fertilizer treatments that avoid environment-damaging nitrogen losses, such as those that occur from nitrogen leaching.

“We like to say Adapt-N was science-created, field-tested and grower-approved,” Shaw says. “This model is not a flash in the pan – it’s been around for a long time. This is a tool that has created its own baseline of nitrogen management. We’ve got hundreds of thousands of acres per season running through this system, and millions of acres over the span of its lifetime.”

The right technology for the right time

Though Yara caters to multiple markets and a varied grower portfolio, for now the company is offering its Adapt-N technology to North American-based corn producers only. Hyper-focusing on a niche market will help scale up the technology for use in additional crops and geographies, remarks Shaw. Although Adapt-N is focused on corn, other crops such as wheat are actively being explored and will someday be available for nitrogen modeling as well.

Adapt-N’s web-based system and integrations into popular farm management information systems gives operators complete control in how they configure individual fields. Growers simply plug in vital data like variable yield zones, while key details such as soil type, slope and weather are already factored in by the software.

Shaw says, “You can utilize previous nitrogen and manure applications, or enhance efficiency products. It goes through the whole gamut of anything that integrates into the nitrogen equation. The tool then feeds 13 different models that work together to create a nitrogen recommendation you can then take to your field. We say it’s a nitrogen recommendation ‘when you need it, where you need it.’”

Recommendations are created every 24 hours, meaning farmers can let the software run by itself over an entire season. Although Yara has a full suite of nitrogen containing products, Adapt-N does not tout any particular product to use for nitrogen. That decision is left to the producer.

Adapt-N instead provides a nutrient recommendation based on nitrogen deficit, giving farmers freedom on what product they will ultimately employ. Shaw says the company is a committed partner of the 4R nutrient stewardship program, promoting fertilizer use through the framework of “the right source, right rate, right time and right place.”

“Adapt-N is a profitable tool with a side of sustainability—that’s the way it’s always been put into the market,” says Shaw. “When you optimize the use of nitrogen, you’re reducing the amount of loss going into the watershed or into the air. As you get more precise with those four Rs, you’re ensuring that nitrogen is being utilized by the plant in the most efficient way possible.

“The opportunities are endless when it comes to any crop that uses nitrogen—we don’t see any change from that,” Shaw says. “The four Rs are scalable, meaning you can get more specific with the management practices of each one. Adapt-N allows us to manage nitrogen in season, or pre-season, based off the information actively happening given the field specific conditions.”

Shaw has been working to integrate with other farming software systems, bolstered by a technology poised to change the industry’s nitrogen management practices now and into the future.

“My goal is to make Adapt-N the traditional nitrogen management practice—to take those growers from where they are now and help them to understand their nitrogen better, ultimately increasing their profitability through that process.” Shaw says. “At the end of the day whenever they get a nitrogen recommendation, our goal is to have it coming from the Adapt-N model.”

The cooperative is utilizing Raven’s driverless system for its own processes, along with a portion of its 6,300 member-growers in North and South Dakota. Using the innovation, Agtegra hopes to streamline operations through a high-tech platform that transforms existing equipment – whether a spreader, sprayer or spinner – into an autonomous machine.

The cooperative is utilizing Raven’s driverless system for its own processes, along with a portion of its 6,300 member-growers in North and South Dakota. Using the innovation, Agtegra hopes to streamline operations through a high-tech platform that transforms existing equipment – whether a spreader, sprayer or spinner – into an autonomous machine.

Erich Eller, a long-time industry veteran and the owner of independent crop consulting business ForeFront Ag Solutions, has experienced the shift to a just-in-time agronomic approach firsthand. It’s his job to help customers use the latest technologies to improve production and the bottom line.

Erich Eller, a long-time industry veteran and the owner of independent crop consulting business ForeFront Ag Solutions, has experienced the shift to a just-in-time agronomic approach firsthand. It’s his job to help customers use the latest technologies to improve production and the bottom line.